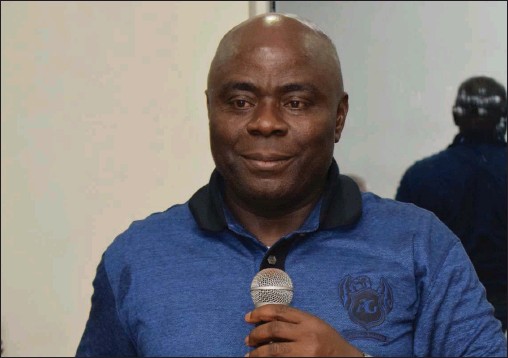

Mr Godwin Izomor is the Managing Director of the MG Vowgas Group, a fabrication company on Engineering, procurement, construction and Installation, servicing the oil and gas and marine sector.

He spoke on various challenges that hinders growth of indigenous companies, what government should do to improve the power sector and curb insecurity in the country to boost businesses for economic growth and development, our Correspondent Edith Ike-Eboh was part of team that spoke to him after the tour of the fabrication yard in Port Harcourt.

Please sir, tell us who you are

My name is Godwin Izomor, I am the Managing Director of MG VowGas Group. We are into oil and gas servicing; basically we are into fabrication construction, EPCI (Engineering, Procurement, Construction and Installation) that is the meaning of EPCI.

Our work cut across all the areas of oil and gas industries, we are also into marine. If you tour with us, you will see the various fabrications on marine vessels.

And by next year, by the grace of God, we are going to build the first Nigerian offshore loading facility either in form of FPSO or just a loading platform with all the skill with all the modules on top of it. Also, we are going to build the first ever Nigeria modular refinery here in this fabrication yard next year and we are already in a design process and by the grace of God, before the end of the year, we will decomponent and will still invite the press to see the various fabrication of this component, of all, the first Nigerian fabricated modular refinery.

You have a huge investment here, what is the investment profile?

The Nigeria Content Development and Monitoring Borad (NCDMB) under categorized us in terms of finance based on what we have spent. Based on the certificate they issued to us, they under quoted our worth. They quoted 125 million dollars but the facility is over 175 million dollars.

How did the Journey start?

The Journey started in 2009, May 1, precisely in my parlour in Wuji here, because I have a house in Wuji here and that was how the journey started. I recruited two other staff, Victor and Aliyu. Victor was earning N35, 000 then and Aliyu N25, 000. I had no salary I just told them that God is taking us somewhere that we should work.

By the time victor left us last year, he was earning about a million naira in the space of ten years because they have been with us from the scratch. But you know in Nigeria, everybody likes to aspire and he discovered that it is time for him to go to do something for himself or for others. But the journey has not been easy.

Today, we have over two hundred and thirty something staffs but that is a journey of three people from 2009.

The only thing that I can tell you is that what keeps us strong is God. I can say that whatever we have achieved today is not just a combined effort of myself but dedicated staff; especially the technical guys who have supported us and all my staff that have been faithful even when there is no money, they are still working with us.

What do you think government should do to help indigenous companies like yours to grow?

The government has made it clear and that is what NCDMB is doing and fighting. Now they want to expand local content to other sectors of the economy.

Government should leave business for businessmen and focus on providing enabling environment. If there is enabling environment, business will thrive. Power should be created, when we go on tour of the facility, you saw the six megawatts of power that we are using to power this yard and ordinarily, it is costing us so much.

If we have a standard generating system in Nigeria, the money I am spending in providing power to run this place, would have been part of the money we would have used to create jobs for the economy; but we spend so much on security and power generation.

There are several ways that government can encourage investors to invest in power generation in Nigeria. For now, there is collaboration between VowGas and Schneider. We are building in-house substations to support power generation, but what government needs to do is to encourage the private sector to invest in power generation.

Power Generation is cheaper when you do it in locality process.

The first thing the government of Nigeria should do is to remove power sector from the exclusive list for local companies to start investing in different locality.

When the power generation is removed from the exclusive list, you will see investors taking every aspect of the country. You will see investors coming. Nigeria is a huge country and a huge economy that anybody is ready to invest and power is one of the key areas. Nigeria must unlock the power sector for investors to come. If they did not unlock NITEL, nobody would have had GSM up till now. So, we have to break the power sector for businessmen to come in to invest. That is the only way we can achieve power generation in Nigeria. If anybody tell you that you have to award contracts for transmission lines and power generation that Nigeria will get power in the next 20 years, it is a lie.

An EPCI like yours, please, can you tell us the challenge you face and how you tackle them?

The challenges are so many, NCDMB have to work fast so as to categorize the companies, because you cannot merge us with a company that has no office, no facilities and you cannot tell us to quote. That means that they will under-quote and we will be gone out of business because we have huge overhead cost. So one of the challenges we have is that the industry should discourage lowest bidder instead of capacity to deliver the project.

You are aware that today there are jobs that they give to consulate contractor’s that they have not been able to deliver in Mobil, Mobil had to cancel those contracts, it is because those people do not have facilities; they do not have anything; they are just consulate contractors who register in NAPIMS and they send them registered bills; they quote anything they can quote and at the end of the day they cannot deliver such services.

We have to tell NAPIMS and the International Oil Companies (IOCs) to disallow lowest bidder ideas because lowest bidder is going to kill local companies; those who are struggling to build facilities like ours; lowest bidding will kill them. So what we need to do is, we have to encourage who is qualified to and have the capacity to deliver the project should be the first thing the IOC should consider.

Then secondly, the challenge of security. We spend money even going to the location where we work. We spend heavy money on security. Where I am working in Agip, we have two gunboat and fifteen personnel. In Chevron, we have two gunboat and fifteen personnel. Constantly, we are spending and those things are not cheap. You spend huge amount of money and the salary scale here, what I pay my workers is about 53 million naira monthly, while my expenses for security is almost 50 million naira monthly.

Can you equate the money spent so far to the contracts you have gotten with IOCs? Are you satisfied with their compliance based on the facilities you have here on ground?

Basically, we have spent close to 175 million dollars in this place but the issue of IOC certify with us. One of the key thing is that the IOC look at your certification in quality; your certification in Health, Safety and Environment (HSE) because these are some of the things that we hold dearly. We have ISO 2015 which is quality and only few companies in Nigeria have achieved ISO 2015 based on quality of fabrication, not just quality on anything, but on fabrication.

We have the best quality management system in Nigeria and the only company I can see in fabrication that have quality management system that have just achieved this recently is LADOL. Its only LADOL that have achieved the ISO 2015 policy management system outside that I don’t think anybody in fabrication have achieved that.

Tell us 10 years from now, where do you see Vowgas to be.

By the grace of God, in ten years from now, from what I have outlined, the first thing we are going to do, we are concentrating, as from next year, in building the first modular refinery. That is one. Two, we are going to invest heavily with our partners in ship building,

We have Brass, we have Brass and Bonny because we are considering, our partners are considering whether Bonny have the landmass for that investment

Secondly, Brass has a lot of land for us to play with. We are going to compare which one is the best place suitable for us because we must reduce capital flight for us here in Nigeria, We make so much money but we import almost everything. The second thing is that we have to appeal to government. Most of the steel we need, we are a steel company, we fabricate everything from steel. Every steel we use today is imported, either from China,Ukraine or Germany. We cannot continue as a country; it is a huge amount of money that is been shipped out of the country.

The annual expenses we use to import steel into this country is enough to set up another steel company in Nigeria. So, we must encourage the federal government to make sure that in the next one or two years, the Ajaokuta steel company is fixed to produce hot sheet plates for our fabrication.

Sir you talked about more projects in Security and collaboration with NCDMB?

Presently, we work with the research department of the Ministry of Defence to build the first Nigeria air boat. The air boat have the capacity and speed of 100 kilometer per hour, and the air boat will use the propeller that is used for airplanes to power it and it will power. Between now and January, we are going to launch it and we will be inviting the Chief of Army Staff to come and commission it.(NAN)